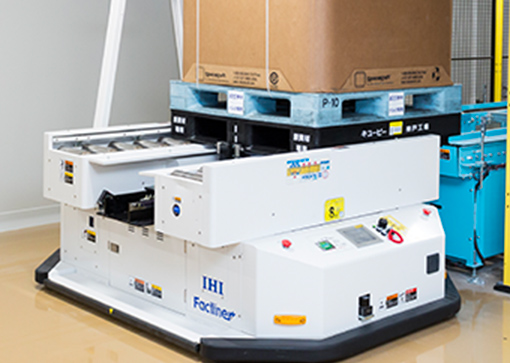

Fact Liner

A Fact Liner is a trackless carrier that can be easily combined with other logistics system and material handling equipment

through the use of numerous transfer devices; such as roller conveyors, push-pulls, and lifters.

Both magnetic-guided AGVs and laser-guided AGVs can navigate spin turns and traversal movements,

enabling efficient and unmanned transport through complex routes.

Lineup

Standard AGV

Standard LGF (Laser Guided Forklift)

Roll Transport AGV

Low-floor AGV (Freezer Compatible)

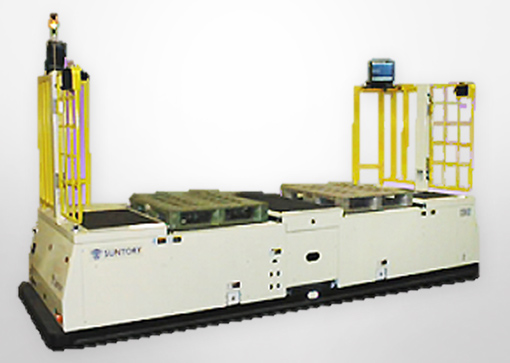

Double Pallet Transport AGV

IHI caters to the diverse needs of our customers with a wide-ranging lineup.

Navigation Systems

- IHI's Fact Liners are compatible with both magnetic and laser guidance systems.

- IHI offers optimal navigation solutions based on the implemented system.

Magnetic guided System

Pictured is an example using adhesive magnetic tape |

|

| Navigation System | A thin and flexible magnetic guide path (made with permanent magnet) is embedded in the floor. Installation of stop and deceleration markers are not required. |

|---|---|

| Flooring Installation Work | Installation work is required to embed the guide paths into the floor. (Installation work is not required when adhesive magnetic tape is used) |

| Layout Modification | Possible with flooring installation work (to install the guide paths) |

| Stopping Capability | ±10mm |

| Other Features | Guide paths adopt the permanent magnets that can withstand dirt and wear and tear by being stepped. The embedded-type system do not require any maintenance or concern for disconnection. |

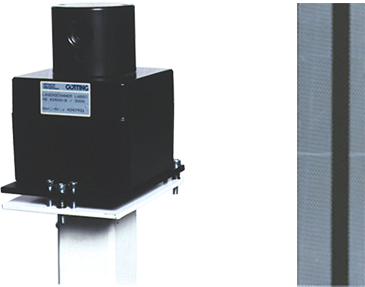

Laser-guided System

Laser oscillator Reflector |

|

| Navigation System | Simple attachment of laser reflector to walls and pillars. No markers are required. |

|---|---|

| Flooring Installation Work | No floor construction is required. No dust will be generated from the installation. |

| Layout Modification | Possible to modify as you wish. A change of route is easily achieved with the controller. |

| Stopping Capability | ±5mm |

| Other Features | The reflectors are semi-permanent and have no layout constraints. |

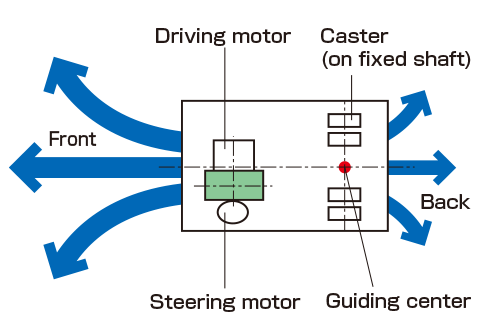

Steering system

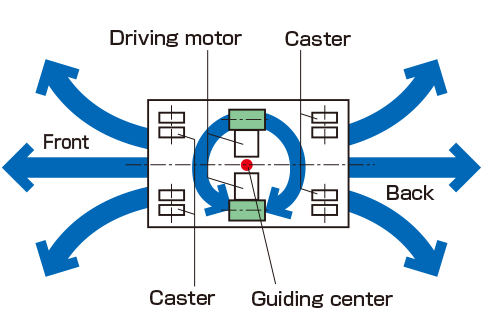

Front-wheel steering system

Power wheel steering system

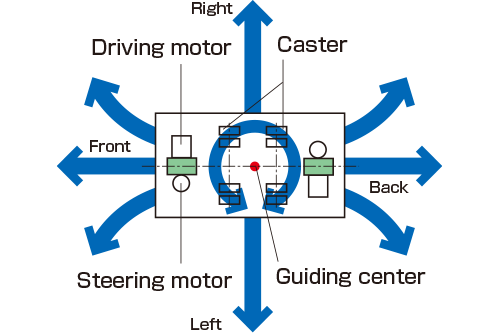

Independent wheel steering system

Charging Systems

- IHI offers charging systems tailored to your layout and operating conditions to maximize your transportation capabilities; such as automatic battery swaps, automatic auxiliary battery charging, automatic fast charge, and manual charging (replacement), etc.

| Automatic battery swap system | Automatic auxiliary battery charging | |

|---|---|---|

| Pros | Achieves high rate of utilization (Approx. 99%) *1 |

Requires no manpower・inexpensive |

| Cons | Some space is required to install the automatic replacement device | Not suitable for systems with high utilization rates |

| Automatic fast charge | Manual charging (replacement) | |

|---|---|---|

| Pros | Achieves high rate of utilization (Approx. 83%) *2 Small battery sizes are ideal for compact vehicles |

Inexpensive |

| Cons | Both battery and charging devices are expensive | Manpower required |

*1 Example: the battery is replaced once every 8 hours. Time required for replacement = 5 minutes. Utilization rate = (8 x 60 - 5)/(8 x 60) = 99%

*2 Example: the battery is charged after every task. Time required for 1 task = 5 minutes. Time required for 1 charge = 1 minute. Utilization rate = 5 / (5 + 1) x 100 = 83%

Safety Features

- Various safety measures are implemented to enable workers to operate comfortably alongside the vehicles.

- The ground control computer comes with UPS as standard to prevent data loss in the event of a power outage.

- All control devices and applications are designed to be failsafe.