Skypod

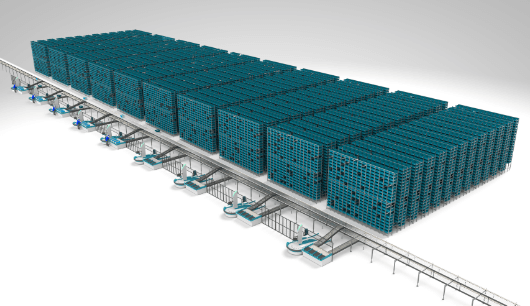

Skypod robot is autonomous picking system which moves in 3 dimension.

The robot can take BIN from 12mH rack, and transports to picking station in a short time.

Skypod makes operation in logistics warehouse much more efficient and automated.

400 order lines per picking station!!

Skypod basic function

Fill items into bins

(Replenishment)

To replenish items, picker just put the item into empty bin transported to picking station. 「Astar」 manages stock of Skypod system.

Pick items from bins

(Preparation)

Skypod robot transports bin to picking station, so picker can continue picking operation without walking around the warehouse.

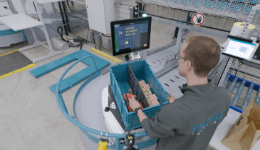

Picking information is displayed

on the monitor

The picker simply picks the items as instructed on the monitor.

Skypod features

Goods to Person system

Picker can stay at picking station and concentrate on their picking work.

Skypod robot climbs up and down the racks, retrieve the bin and transports to the picking station on behalf of picker.

This makes it possible to finish picking operation about 5 times faster than non-automated warehouse system.

Climb up and down rack

Retrieve bin

Transportation

Picking Station

Astar

Astar is the software for Skypod System to manage Skypod Robots and pickers. Astar decides the whole operating status of Skypod robots and pickers, and gives instruction to the robots by "which product should be taken out from which rack", "which robot should go", and "which picker should perform which operation".

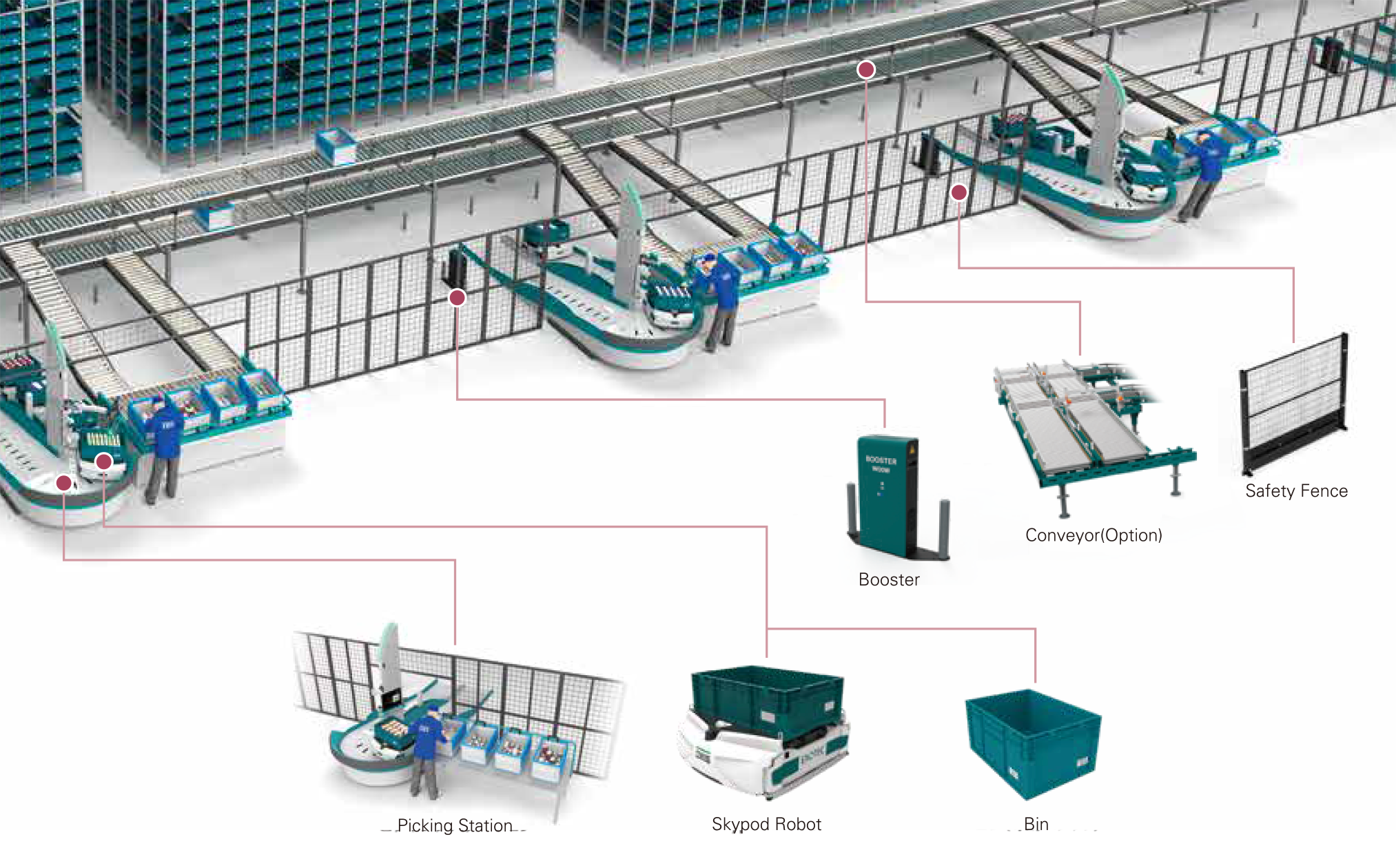

Picking Station

Robot transports target item to the picking station. The order mover type can easily connect Skypod system to the conveyor system and improve the efficiency of picking operation. It automatically supplies empty containers and evacuates full containers which the picking has been completed.

Manual Type

Order Mover Type

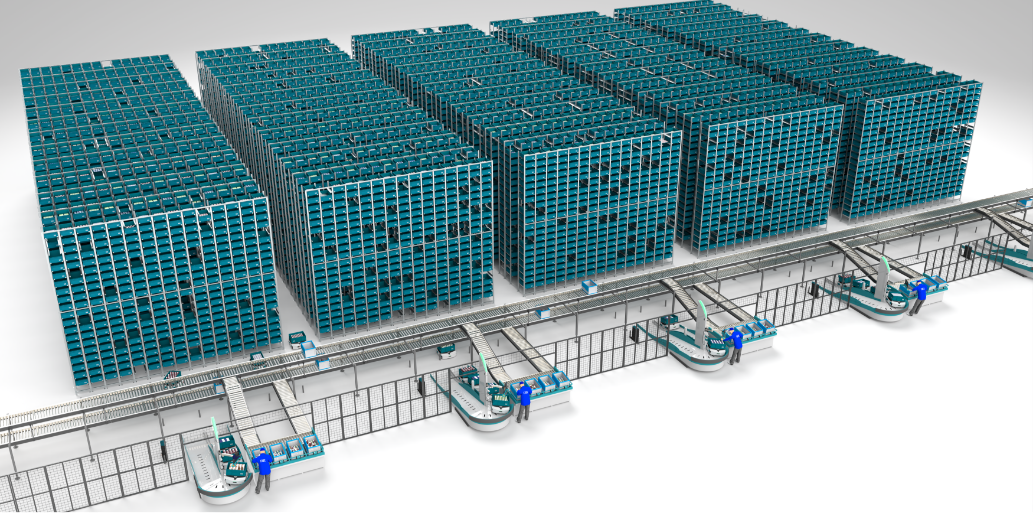

Scalability

According to the size of the warehouse, the number of Skypod robots and the size of system can be adjusted flexibly. In addition, Skypod can easily expand the system, according to customer’s business scale expansion and business growth.

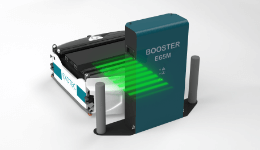

Charging

Skypod robot goes to the booster(quick charging station) by themselves once an hour to charge. Picker doesn’t need to charge robot and it improves work efficiency.

Quick charging station

Combination

with picking robot

Skypod can combine with piece picking robot. It will improve efficiency and save the manpower.

Specification of Skypod Robot

| Payload | 30 kg |

|---|---|

| Speed | 4m/s |

| Weight | 50kg |

| Dimensions | 650 × 650 × 300mmH |

| Obstacle detection | Laser scanner |

| Guidance | Scanner |

| Energy | Lithium Battery |

| Charging | Chargin station 5min/h |

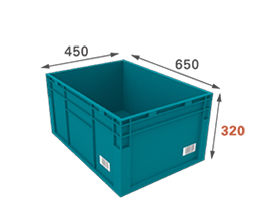

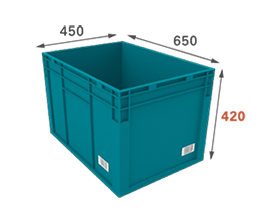

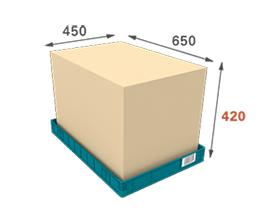

Bin(plastic tote dedicated for skypod) / Tray

Cartons up to 400mm×600mm×400mmH can be put on the trays

Tray’s bottom thick: 20-25mm